Condensers and Oudh

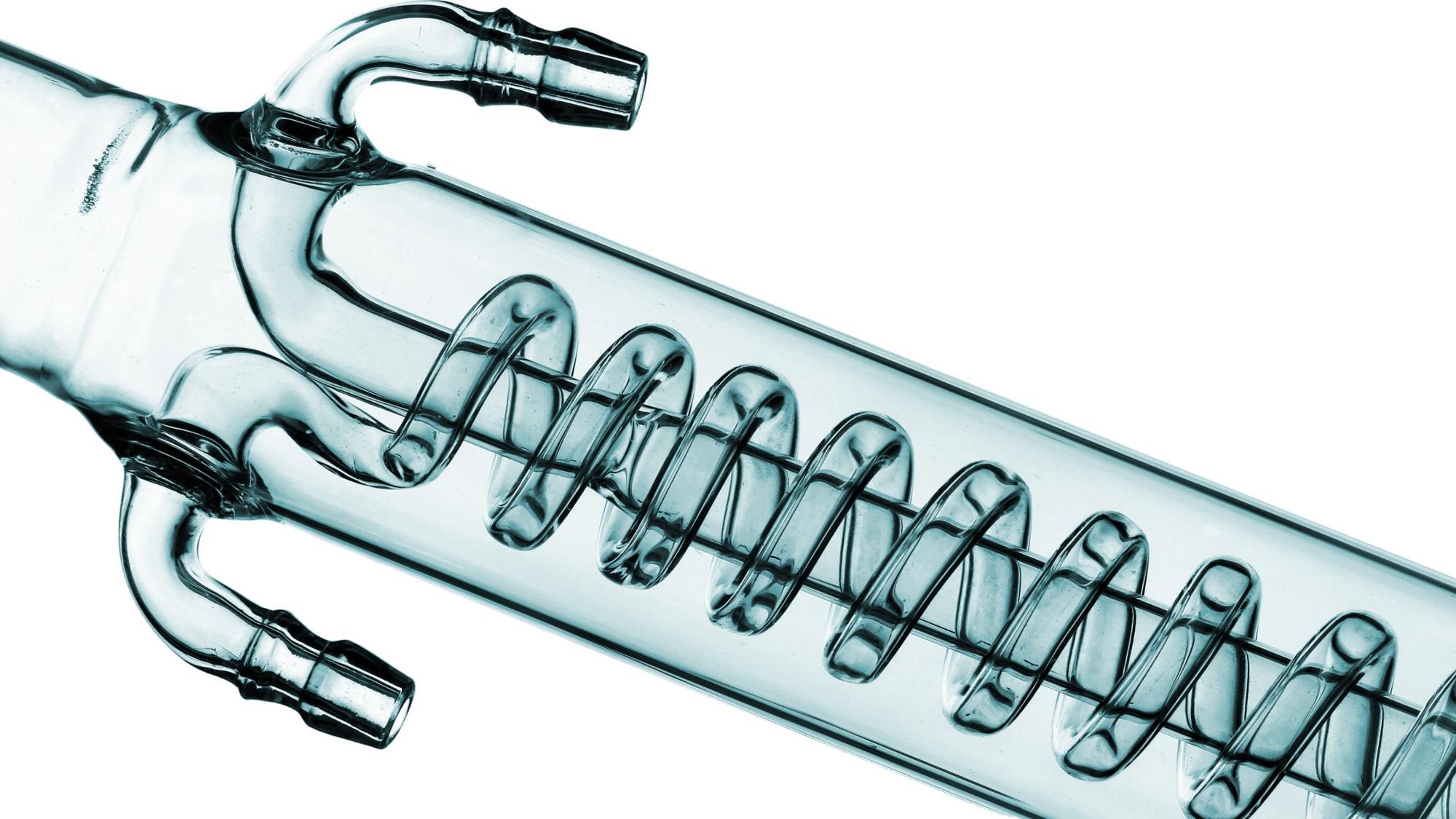

Last week we spoke about pots for oudh distillation. Pots form the base of where the oudh wood is boiled. The boiling produces steam and the steam must be cooled down into a distillate in order to separate the oil from the water. This is where the next piece of the puzzle comes in, and that is the Condenser.

What is best for Oudh?

The most important elements for designing your condenser is understanding the properties of the vapor/steam that comes from your pot. To understand the vapor/steam properties you need to experiment using chemistry and physics fundamentals. There are a few variables involved but I will list the most important ones;

1. How hot is the vapor going to be

2. What is the composition of the vapor. The reason this is important is because different elements cool at different rates and this will contribute to the amount of cooling required.

3. Your cooling water temperature and the temperature of this water after heat transfer

4. The flow rate of your cooling water.

Next the HTC (heat transfer coefficient) has to be calculate, this can be a bit complicated but, easy enough to get down pat with practice. The HTC is about the most important value you will have to calculate. Cooling water is another area that many distillers make mistakes in. They will use a small tank, or a bucket, or tub, to store the cooling water or they will use ice cooled water and then just sink the condenser elements in there, or through it. The issue with small containers is the lack of flow which drops the HTC value which in turn impacts how well the vapor turns into liquid.

If someone wanted to guess a HTC value and not calculate one, then for water flowing in tubes, the HTC aka W/m2K would be between 500-1200.

Capacity of the Condenser

The next step is to work out the length of the condenser and the water flow rate required based on the systems parameters. As an example;

1. 100 C

2. Oil + Water

3. Cooling Water in 10 C , Heated Water Out 37 C

4. W/m2K 500

For this example then we will need a 1.05m condenser with 12mm tubing, and water flow rate of 0.8 L/m. (I have left out the detail in the calculation as this interface does not support equation writing)

If one wished to shorten the condenser then this can be achieved by increasing the flow rate of the cooling water. Reducing the temperature of the cooling water helps as well, however increasing the velocity of the water passing through the cooling system is much better. In simple terms blowing your tea will cool it down much faster than holding it in your hand, even on a cold day.

Effects on the Oil

Finally the best condensers are those that expose the hot vapor/steam to the most surface area of cold, and allows a high flow rate of the cold cooling water through the system. The steam from the pot must be cold in an effective timely manner, in order to capture the complexity of the oil, if the steam is cooled too fast or too slow, then it will have side effects on the oil. If the steam does not cool down then it can leak from the system if the system is an open system. If the system is a closed system then this can return back into the pot and cause further break down of the fragrant compounds which will lead to undesirable side effects such as the oil being too top heavy or floral.